Supply chain attacks have become a significant and evolving threat, with their sophistication and frequency on the rise. Gartner predicts that by 2025, 45% of organizations worldwide will have experienced attacks on their software supply chains, a three-fold increase from 2021.

Businesses rely on a complex network of suppliers and partners to deliver goods and services. This intricate web of dependencies, however, also presents a growing vulnerability – the cyber supply chain. Cybercriminals, recognizing this Achilles’ heel, have increasingly turned their attention to supply chain attacks, exploiting the trust relationships within these networks to gain access to sensitive data and disrupt critical operations.

These attacks can take various forms, from infiltrating software development environments to compromising supplier networks. The consequences of data breaches can cause financial losses, reputational damage, and operational disruptions.

A notable example of a supply chain attack is the 2020 SolarWinds hack, where Russian hackers infiltrated the software company’s supply chain, inserting malicious code into its Orion network management software. This backdoor allowed the attackers to access the systems of numerous high-profile organizations, including the US government, Microsoft, and FireEye.

As attacks become more sophisticated, organizations must continuously adapt their strategies for cyber supply chain risk management to stay ahead of the curve. By proactively addressing these risks, businesses can safeguard their critical data, maintain operational resilience, and protect their reputation.

What is Cyber Supply Chain Risk Management (C-SCRM)?

C-SCRM is a critical process that involves identifying, assessing, and mitigating the risks associated with the distributed and interconnected nature of IT/OT product and service supply chains. It’s an ecosystem composed of various entities with multiple tiers of outsourcing, diverse distribution routes, assorted technologies, laws, policies, procedures, and practices.

The same factors that allow for low cost, interoperability, rapid innovation, a variety of product features, and other benefits also increase the risk of a compromise in the supply chain. These risks may include the insertion of counterfeits, unauthorized production, tampering, theft, the insertion of malicious software and hardware, and poor manufacturing and development practices in the cybersecurity-related elements of the supply chain.

C-SCRM involves managing these risks throughout the entire life cycle of a system, including its design, development, distribution, deployment, acquisition, maintenance, and destruction. It can be achieved by identifying the cyber supply chain, understanding cyber supply chain risk, setting cybersecurity expectations, auditing for compliance, and monitoring and improving cyber supply chain security practices.

Why is C-SCRM Important?

Cyber Supply Chain Risk Management (C-SCRM) is critically important due to the complex, interconnected nature of modern supply chains and the increasing prevalence of cyber threats. The integration of information, communications, and operational technology (ICT/OT) in supply chains has resulted in a distributed ecosystem where risks can emerge from various sources, including insecure manufacturing practices, tampering, theft, the insertion of malicious software, and the risk of counterfeits.

The financial and reputational impacts of cyber supply chain attacks can be profound and far-reaching. The direct financial consequences of a cyber supply chain attack are often immediate and severe. These costs can include:

- Business Disruption, Downtime, and Remediation Costs: The cost of cyber attacks on supply chains is on average $4.35 million per incident. This includes the costs associated with business disruption, downtime, and remediation efforts.

- Data Loss, Intellectual Property Theft, and Financial Fraud: Cyber attacks can lead to data loss, intellectual property theft, and financial fraud. These incidents can result in significant financial losses for the affected organizations.

- Regulatory Fines and Legal Settlements: Breached businesses may face regulatory fines for non-compliance with data protection laws. For instance, the General Data Protection Regulation (GDPR) in the European Union can impose fines of up to 4% of a company’s annual global turnover or €20 million, whichever is higher, for serious violations.

The reputational damage from a cyber supply chain attack can be even more devastating than the financial loss. This can result in:

- Loss of Customer Trust and Erosion of Brand Equity: A breach can lead to a loss of customer trust and erosion of brand equity.

- Difficulty Attracting and Retaining Talent: The reputational damage from a cyber attack can make it difficult for organizations to attract and retain talent.

- Competitive Disadvantage and Diminished Market Share: Reputational damage can result in a competitive disadvantage and diminished market share.

Compliance with industry regulations is one of the key benefits of implementing a cyber supply chain management plan. Organizations need to stay updated on the latest regulations and standards related to cybersecurity and supply chain management. The National Institute of Standards and Technology (NIST) is responsible for developing reliable and practical standards, guidelines, tests, and metrics to help protect non-national security federal information and communications infrastructure. The private sector and other government organizations also rely heavily on these NIST-produced resources.

The NIST’s revised publication, titled “Cybersecurity Supply Chain Risk Management Practices for Systems and Organizations” (Special Publication 800-161 Revision 1), offers detailed guidance on identifying, assessing, and mitigating cybersecurity risks throughout the supply chain at every organizational level.

Legal obligations also compel organizations to safeguard their supply chains from cyber threats, which include ensuring the security of their products and services, protecting customer data, and complying with data protection laws. Contractual agreements with suppliers and partners should include clauses related to cybersecurity, helping ensure that all parties in the supply chain are committed to maintaining high standards of cybersecurity.

In the event of a cyber incident, organizations need to have a legal framework in place for responding, which includes reporting the incident to relevant authorities and communicating with affected parties. Organizations need to implement a risk management approach to C-SCRM, which includes identifying potential risks, assessing their impact, and implementing measures to mitigate them. Lastly, training and awareness programs can help ensure that all employees understand their legal responsibilities related to C-SCRM.

Common Types of Cyber Supply Chain Attacks

Understanding the types of cyber supply chain attacks is the first step toward developing effective strategies for cyber supply chain risk management. Here are some common types of cyber supply chain attacks:

- Commercial Software Products Attacks: These attacks target commercial software products used by hundreds or even thousands of companies. If a software company’s system is breached or its product’s integrity is compromised, a supply chain attacker gains access to numerous targets. One common method is compiler attacks, where the compiler is used to insert malicious code into the translation it produces.

- Open-source Supply Chain Attacks: Open-source software is vulnerable as anyone can contribute to the development of a program. Open-source software solutions have been identified as particularly vulnerable, as they are open to contributions from anyone towards the development of a program. Unfortunately, hackers have taken advantage of the open-source nature of these solutions and have intentionally programmed vulnerabilities into them, thereby making it easy for them to introduce threats to companies that use the software produced.

- Foreign-sourced Threats: In some countries, software products may contain malicious code that the government demands the producer to include. Malicious actors can infiltrate companies and sneak their code into otherwise legitimate products.

- Stolen Certificates Attacks: If a hacker steals a certificate used to vouch for the legitimacy or safety of a company’s product, they can peddle malicious code under the guise of that company.

- Hardware Supply Chain Attacks: Threat actors compromise physical hardware components like USB drives and phones to infect other devices.

- Software Supply Chain Attacks: Cybercriminals infiltrate a software vendor’s environment or code base and make changes to it to send harmful code and updates to customers.

- Upstream Server Attacks: These are the most common types of supply chain attacks, in which a malicious actor infects a system that is “upstream” of users, such as through a malicious update, which then infects all the users “downstream” who download it.

- Advanced Persistent Threat (APT) Group Attacks: Advanced Persistent Threat (APT) groups are sophisticated cybercriminal organizations that conduct sustained cyberattacks, often going undetected in a network while stealing sensitive data. These groups have been known to carry out supply chain attacks. For instance, the Lazarus APT group has been reported to employ supply chain attacks using sophisticated tools such as MATA.

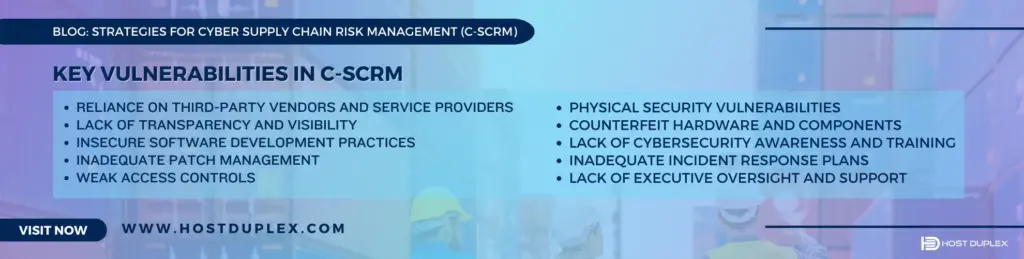

Key Vulnerabilities in Cyber Supply Chain Risk Management

The key vulnerabilities that organizations face in C-SCRM must be addressed to strengthen defense mechanisms and ensure a secure supply chain. Below are the most critical vulnerabilities that require attention:

- Reliance on Third-Party Vendors and Service Providers: Organizations often outsource critical functions to third-party vendors and service providers, entrusting them with access to sensitive data and systems. These third-party entities may not have the same level of cybersecurity maturity or risk management practices as the parent organization, increasing the likelihood of compromise.

- Lack of Transparency and Visibility: The complex and often opaque nature of global supply chains makes it challenging for organizations to maintain complete visibility into the security practices and risk profiles of their suppliers. This lack of transparency can hinder efforts to identify and mitigate potential vulnerabilities.

- Insecure Software Development Practices: Software supply chains are particularly vulnerable to attacks that exploit flaws in software development practices. These vulnerabilities can be introduced intentionally by malicious actors or inadvertently through coding errors or insecure coding practices.

- Inadequate Patch Management and Vulnerability Remediation: Failing to promptly address known vulnerabilities and apply timely patches can leave systems exposed to exploitation. This is particularly critical in the supply chain context, as vulnerabilities in widely used software components can affect a large number of organizations.

- Weak Access Controls and Identity Management: Improper access controls and poor identity management practices can grant unauthorized individuals access to sensitive data and systems, increasing the risk of data breaches and malicious activities.

- Physical Security Vulnerabilities: Physical access to supply chain infrastructure, such as manufacturing facilities and data centers, can provide attackers with opportunities to tamper with hardware, install malware, or steal sensitive data.

- Counterfeit Hardware and Components: The use of counterfeit hardware and components can introduce embedded malware or vulnerabilities into supply chains, potentially compromising the integrity and security of critical systems.

- Lack of Cybersecurity Awareness and Training: Employees throughout the supply chain, from software developers to manufacturing personnel, may lack adequate cybersecurity awareness and training, making them more susceptible to social engineering attacks and phishing scams.

- Inadequate Incident Response Plans: Organizations often fail to develop and test comprehensive incident response plans, leaving them unprepared to respond to cyberattacks that target their supply chains effectively.

- Lack of Executive Oversight and Support: Cybersecurity risks in the supply chain often fail to receive adequate attention and support from senior management. This lack of executive oversight can hinder efforts to allocate resources, implement effective risk mitigation strategies, and foster a culture of cybersecurity awareness across the organization.

What are the Challenges in Implementing C-SCRM?

Implementing Cyber Supply Chain Risk Management (C-SCRM) is a complex task fraught with numerous challenges. One of the primary hurdles is the lack of visibility into the supply chain. This includes understanding the various entities involved, their roles, and the potential risks they pose. Compounding this issue is the inherent complexity of supply chains. With multiple tiers of outsourcing, diverse distribution routes, and a variety of technologies, laws, policies, procedures, and practices, managing and mitigating risks becomes a daunting task.

Budget constraints further complicate the implementation of comprehensive C-SCRM strategies. Limited financial resources can hinder the ability to invest in necessary security measures and technologies. Additionally, there can be resistance from suppliers when asked to comply with certain security measures, posing another challenge in ensuring the security of the supply chain.

Identifying the inherent risks can be incredibly difficult within a complex ecosystem of third-party vendors and multi-tier suppliers. Keeping up with the rapid pace of technological change, especially when it comes to updating and modernizing infrastructure and applications, adds to these challenges.

Organizations may also lack the necessary threat intelligence to make informed decisions about risk management. Ensuring that the supply chain can withstand and quickly recover from disruptions, thereby maintaining operational resilience, is a significant challenge. Finally, entities may struggle with conceptualizing risk due to a lack of threat information, an underappreciation of their own vulnerabilities, or a lack of a framework for making resource decisions.

What are the Best Strategies for Cyber Supply Chain Risk Management?

The best practices that organizations can adopt to enhance C-SCRM are:

1. Integrate C-SCRM across the Organization

The first and foremost practice is to integrate C-SCRM across the organization. This means that C-SCRM should not be confined to a single department or function but rather be an enterprise-wide activity. The rationale behind this approach is that cyber risks can originate from any part of the organization and can impact multiple areas. Therefore, a siloed approach to C-SCRM can lead to gaps in risk management and can limit the effectiveness of the organization’s response to cyber threats.

2. Establish a Formal C-SCRM Program

Establishing a formal Cyber Supply Chain Risk Management (C-SCRM) program is an essential step in strengthening an organization’s defense against supply chain threats. This program involves creating and implementing robust governance policies, processes, and procedures that enhance visibility and transparency across software and product development teams. Organizations can effectively manage potential risks by clarifying roles and responsibilities, selecting appropriate tools, and defining policies for the development lifecycle.

A key aspect of this program is the adoption of a zero-trust mindset, where the code and application development process are not trusted by default. Organizations should approach their C-SCRM program comprehensively, encompassing governance, procedures, policies, tools, and processes and defining clear roles, responsibilities, and cross-functional collaboration. This approach also includes establishing testing procedures and service-level agreements (SLAs) to ensure the resilience and security of the software supply chain.

3. Know and Manage Critical Suppliers

Knowing and managing critical suppliers is a key practice in Cyber Supply Chain Risk Management (C-SCRM). Critical suppliers are those whose failure could have a significant impact on the organization. The process involves identifying and constantly monitoring vital components such as CI/CD pipelines, repositories, developer access, and adherence to policies and compliance standards. Organizations must also assess all vendors thoroughly, ensuring that vulnerabilities are remediated before sharing any information, data, or services. Understanding the risks associated with each vendor, including the type of access they have and the data they can access, is crucial. This comprehensive approach helps maintain a secure supply chain and manage third-party risks effectively.

4. Understand the Organization’s Supply Chain

The organizations should have a clear and comprehensive knowledge of their supply chain, including the following aspects:

- The components of the supply chain, such as the products, services, processes, technologies, and entities involved in the delivery of value to the customers.

- The relationships among the supply chain components, such as dependencies, interdependencies, contracts, and agreements, govern the interactions and transactions among the supply chain actors.

- The risks associated with the components and relationships of the supply chain, such as the potential threats, vulnerabilities, and impacts that could affect the security, quality, and performance of the supply chain.

- The controls that are implemented to manage the risks of the supply chain, such as the policies, procedures, standards, and best practices, are designed to prevent, detect, and respond to cyber incidents and ensure compliance with legal and regulatory frameworks.

5. Closely Collaborate with Key Suppliers

Establishing collaborative relationships with key suppliers enhances communication and information sharing, fostering a shared ecosystem that benefits both parties. Utilizing every opportunity to increase visibility with third-party suppliers is crucial in managing risks effectively. The following are the key steps in collaborating closely with key suppliers:

- Establish Strong Relationships: Establishing strong relationships with key suppliers is the first step in close collaboration. This involves regular communication, mutual trust, and a shared understanding of the importance of cybersecurity.

- Share Information: Sharing information about cybersecurity threats, vulnerabilities, and best practices can enhance the security of both the organization and its suppliers. This could involve sharing threat intelligence, conducting joint risk assessments, or providing training and awareness programs.

- Influence Supplier Practices: Organizations can influence their suppliers’ cybersecurity practices through contractual requirements, audits, and other means. This can help to ensure that suppliers adhere to the organization’s cybersecurity standards.

- Jointly Manage Risks: Organizations and their key suppliers can jointly manage cyber supply chain risks by developing and implementing coordinated risk management strategies. This could involve joint incident response planning, coordinated risk mitigation activities, or mutual assistance in the event of a cybersecurity incident.

This collaboration, though sometimes challenging, is vital for early vulnerability detection, thereby preventing significant damage. At the core of this effective management are people, processes, and technology, which, when harmonized through proper communication, enhance the security and efficiency of the supply chain. This collaborative approach helps identify issues and discover visibility gaps, thereby strengthening the organization’s cybersecurity risk management.

6. Include Key Suppliers in Resilience and Improvement Activities

Involving key suppliers in resilience and improvement activities helps to ensure that they are aligned with the organization’s cybersecurity objectives and are prepared to respond effectively to cyber threats. It also provides an opportunity for the organization and its suppliers to learn from each other and improve their cybersecurity practices. Additionally, maintaining regular communication and organizing activities focused on supply chain resilience and security are crucial. Service-level agreements (SLAs) can be used to define responsibilities and standardize security requirements across the supply chain, ensuring suppliers are accountable for cybersecurity incidents and adhere to specified security standards.

7. Continuously Assess and Monitor Supplier Relationship

Assessing and monitoring throughout the supplier relationship involves a continuous process of evaluating the supplier’s performance, quality, delivery, and risk management practices. Here are some steps to follow:

- Risk Assessment: Identify and assess the cybersecurity risks associated with each supplier. This includes understanding the supplier’s cybersecurity practices, the sensitivity of the data they handle, and their compliance with relevant cybersecurity standards and regulations.

- Continuous Monitoring: Implement a continuous monitoring program to track the supplier’s cybersecurity performance over time. This can involve regular audits, vulnerability assessments, and incident response exercises.

- Performance Metrics: Define clear cybersecurity performance metrics and use them to evaluate the supplier’s performance. These metrics can include the number of security incidents, the effectiveness of the supplier’s incident response, and their compliance with cybersecurity requirements.

- Contractual Requirements: Include cybersecurity requirements in contracts with suppliers. These requirements should specify the supplier’s cybersecurity responsibilities and the consequences for non-compliance.

- Collaboration and Information Sharing: Establish mechanisms for collaboration and information sharing with suppliers. This can include sharing threat intelligence, discussing cybersecurity best practices, and coordinating incident response activities.

- Supplier Review and Evaluation: Regularly review and evaluate the supplier’s cybersecurity performance. This can involve conducting supplier audits, reviewing the supplier’s self-assessments, and using third-party assessments.

Moving Forward in Cyber Supply Chain Security

The journey towards robust C-SCRM is ongoing and dynamic. It requires vigilance, adaptability, and a commitment to continuous improvement. As you apply the strategies we’ve explored within your organization, remember that the strength of a supply chain is defined not only by its protective measures but also by its ability to evolve and respond to new challenges. I encourage you to reflect on how these strategies align with your current practices and where there’s room for enhancement.

The future of cyber-supply chain security is shaped by collaboration and innovation. Sharing insights, learning from each other’s experiences, and staying ahead of trends can collectively build more resilient systems.

C-SCRM FAQs

How can organizations implement C-SCRM?

Organizations can implement C-SCRM by developing a comprehensive C-SCRM strategy, establishing a C-SCRM program, conducting regular risk assessments and audits of their suppliers, implementing appropriate security controls and measures, and fostering collaboration and information sharing with their suppliers.

How long does it take to implement a C-SCRM program?

The time it takes to implement a C-SCRM program can vary depending on the size and complexity of the organization and its supply chain, the resources available, and the specific requirements and objectives of the C-SCRM program.

Should I use security questionnaires in C-SCRM?

Yes, security questionnaires can be a useful tool in C-SCRM for gathering information about suppliers’ cybersecurity practices and assessing their compliance with your organization’s cybersecurity requirements.

Do I need to work with legal counsel to develop a C-SCRM program?

Yes, it can be beneficial to work with legal counsel when developing a C-SCRM program to ensure compliance with relevant legal and regulatory requirements and to address any legal issues that may arise in the context of C-SCRM.

What standards should my suppliers meet in terms of cybersecurity?

The specific cybersecurity standards that your suppliers should meet can depend on various factors, such as the nature of the products or services they provide, the sensitivity of the data they handle, and the legal and regulatory requirements applicable to your organization and its supply chain.

How do I know if my suppliers are meeting cybersecurity standards?

You can determine if your suppliers are meeting cybersecurity standards by conducting regular audits and assessments of their cybersecurity practices, reviewing their security certifications and attestations, and monitoring their performance and compliance over time.

7 Best Strategies for Cyber Supply Chain Risk Management (C-SCRM)